Power from Syngas

Syngas, also known as synthesis gas, synthetic gas or producer gas, can be produced from a variety of different materials that contain carbon. These can include biomass, plastics, coal, municipal waste or similar materials. Historically town gas was used to provide a gas supply to many residences in Europe and other industrialised countries in the early 20th Century.

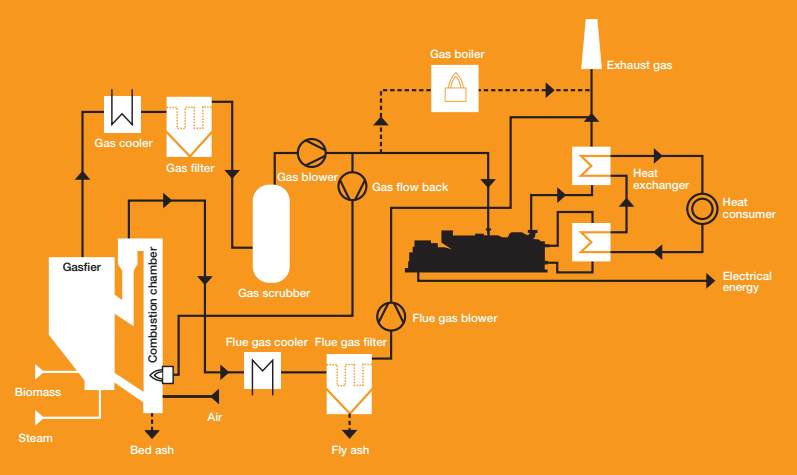

Syngas is created by the gasification or pyrolysis of carbonaceous materials. Gasification involves subjecting these materials to high temperatures, in the controlled presence of oxygen with only limited combustion to provide thermal energy to sustain the reaction. Gasification can occur in man-made vessels, or alternatively could be conducted in-situ as in the gas of underground coal gasification.

Where the fuel to the gasifier is of recent biological origin, such as wood or organic waste, the gas produced by the gasifier is considered to be renewable and so is the power produced by its combustion. When the fuel to the gasifier is a waste stream, its conversion to power in this manner has the combined benefit of the conversion of this waste into useful products.

Benefits of Synthetic Gas

— Generation of renewable power

— Conversion of problematic wastes to useful fuels

— Economical onsite power production and reduced transmission losses

— Reduction in carbon emissions

Syngas Challenges

Steel production processes typically dispose large volumes of speciality gases. Three different process stages – from coal to steel – provide three different gas types: coke gas, blast furnace gas and converter gas.

The composition of syngas is highly dependent upon the inputs to the gasifier. A number of the components of syngas cause challenges which must be addressed at the outset, including tars, hydrogen levels and moisture.

Hydrogen gas is much quicker to burn than methane, which is the normal energy source for gas engines. Under normal circumstances, faster combustion in the engine cylinders would lead to the potential of pre-ignition, knocking and engine backfiring. In order to counter this challenge the engine has a number of technical modifications and the output of the engine is reduced to between 50-70% of its typically natural gas output. (I.e. a 1,063kW engine running on natural gas is comparable to a maximum 730kW engine on synthetic gas).

Post time: Aug-27-2021